Maximizing Efficiency in ODM Combiner Box Manufacturing: A Guide for Modern Factories

2026-01-01

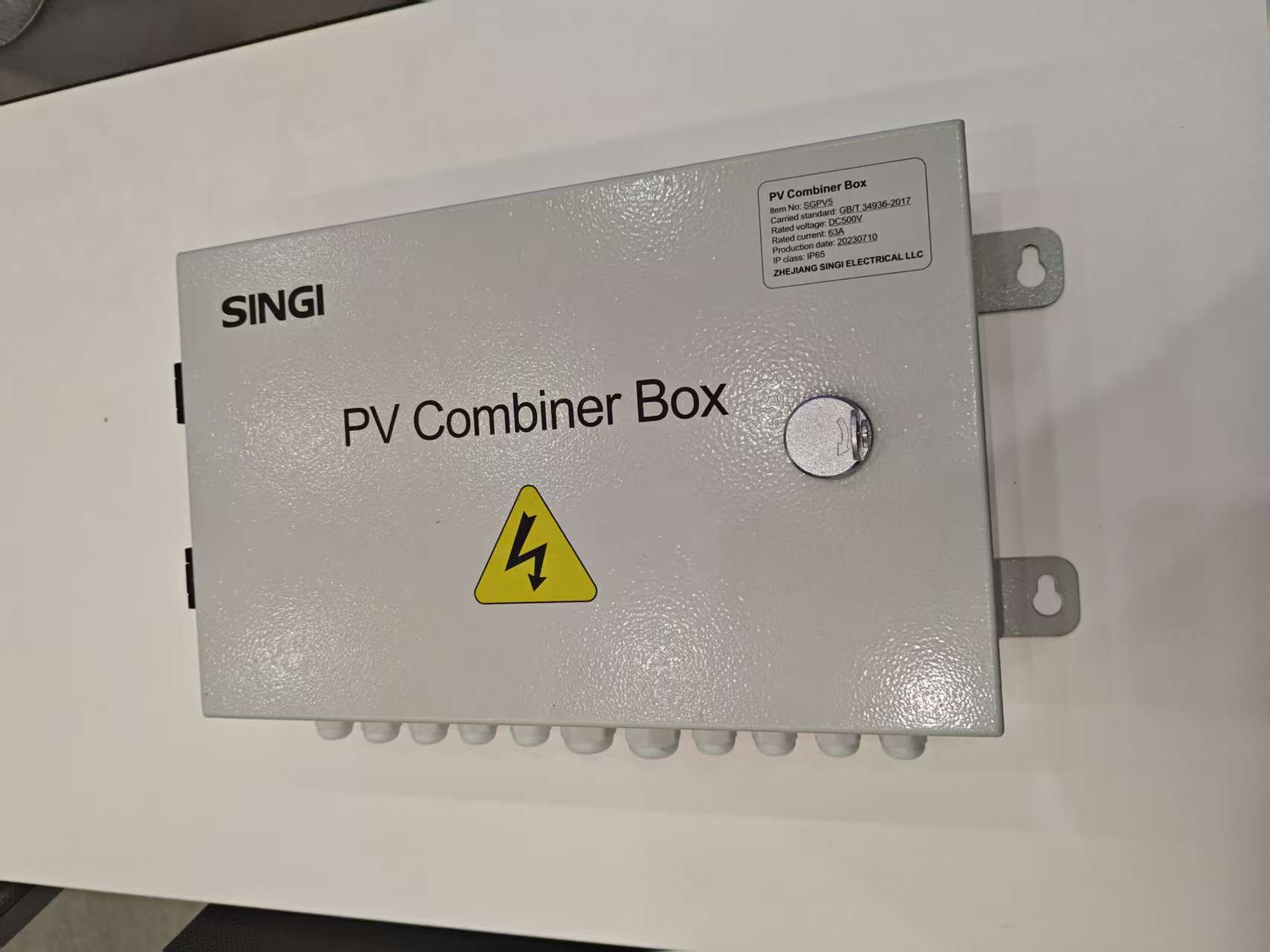

In the fast-evolving landscape of renewable energy, ODM combiner box manufacturing stands as a critical yet often challenging process. As factories strive to keep pace with global demand, efficiency isn't just an option—it's the backbone of competitive advantage. At SINGI, we've seen firsthand how innovative approaches can transform production lines from bottlenecks into hubs of precision and speed. This guide delves into practical strategies that modern facilities can adopt to streamline operations, reduce costs, and boost output without compromising quality. Whether you're a seasoned engineer or a factory manager looking to optimize workflows, the insights ahead promise to elevate your manufacturing game. Let's explore how cutting-edge techniques are reshaping the future of ODM combiner boxes, one efficient step at a time.

Streamlining Assembly Lines for Enhanced Production Speed

In today's fast-moving industrial landscape, optimizing manufacturing processes is key to staying competitive. Streamlining assembly lines focuses on eliminating bottlenecks, reducing downtime, and improving workflow efficiency. By analyzing each step, from material handling to final assembly, companies can identify inefficiencies and implement targeted solutions, ultimately boosting production speed without compromising on quality.

A practical approach involves integrating lean manufacturing principles, such as just-in-time inventory and continuous improvement cycles. For instance, automating repetitive tasks or reorganizing workstation layouts can significantly cut cycle times. This not only accelerates output but also enhances worker productivity and reduces operational costs, fostering a more agile and responsive production environment that adapts quickly to market demands and seasonal peaks.

Beyond internal adjustments, embracing digital tools like IoT sensors and real-time data analytics provides deeper insights into equipment performance and process flows. This allows for predictive maintenance and dynamic scheduling, minimizing unplanned stoppages and ensuring a smoother, faster assembly line that consistently meets or exceeds production targets.

Implementing Quality Control Protocols to Minimize Defects

To effectively reduce defects in any production or service environment, establishing robust quality control protocols is essential. This process begins with a thorough analysis of potential failure points across the entire workflow, from initial design stages to final delivery. By integrating regular inspections and real-time monitoring systems, teams can catch issues early, preventing small errors from escalating into major problems. It's not just about finding flaws—it's about creating a culture where quality is everyone's responsibility, encouraging proactive feedback and continuous improvement among all staff members.

A key aspect of implementing these protocols involves tailoring them to specific operational needs rather than relying on generic standards. For instance, in a manufacturing setting, this might mean deploying advanced sensors and automated testing equipment to check product dimensions and materials with precision, while in software development, it could involve rigorous code reviews and user acceptance testing. Customization ensures that the controls are not only effective but also efficient, avoiding unnecessary bottlenecks and aligning with the unique challenges of each project or product line.

Moreover, ongoing evaluation and adaptation of quality control measures are crucial for long-term success. By regularly analyzing defect data and gathering insights from customer feedback, organizations can identify trends and refine their protocols to address emerging risks. This dynamic approach helps maintain high standards over time, fostering innovation and reliability that set a company apart in competitive markets. Ultimately, minimizing defects through well-implemented controls leads to enhanced customer satisfaction, reduced waste, and stronger brand reputation.

Leveraging Sustainable Materials for Eco-Friendly Manufacturing

In today's industrial landscape, embracing sustainable materials isn't just a trend but a fundamental shift towards responsible production. By integrating resources like bamboo, recycled plastics, and biodegradable composites, manufacturers can drastically cut down on waste and carbon footprints. For instance, using reclaimed wood in furniture design not only preserves forests but also adds unique character to each piece, appealing to eco-conscious consumers who value authenticity.

Moreover, innovative materials such as mycelium-based alternatives are revolutionizing sectors from packaging to construction. These bio-based options decompose naturally, reducing landfill overflow and offering cost-effective solutions in the long run. Companies adopting these materials often see improved brand reputation and compliance with stricter environmental regulations, positioning themselves as leaders in a competitive market.

Beyond immediate benefits, this approach fosters a circular economy where materials are reused and repurposed. By prioritizing durability and recyclability, manufacturers can create products that last longer and minimize resource extraction. This holistic strategy not only safeguards natural ecosystems but also drives economic resilience, making eco-friendly manufacturing a smart, forward-thinking choice for businesses aiming to thrive sustainably.

Optimizing Supply Chain Logistics for Cost-Effective Operations

Supply chain logistics is the backbone of any business aiming to cut costs while boosting efficiency. By focusing on streamlined processes and smarter routing, companies can minimize waste and delays, directly impacting the bottom line. Imagine a warehouse where inventory moves seamlessly, reducing storage fees and speeding up deliveries—it's not just a dream but a strategic advantage.

A key aspect is leveraging data analytics to predict demand fluctuations, allowing for better inventory management and avoiding overstock or shortages. Partnering with reliable carriers and negotiating flexible contracts can also slash transportation expenses. It's about creating a responsive network that adapts to market changes without breaking the bank.

Ultimately, cost-effective operations thrive on continuous improvement, from automating repetitive tasks to fostering collaboration across teams. This holistic approach ensures that every link in the chain, from supplier to customer, works in harmony to drive savings and enhance reliability.

Integrating Smart Technologies to Boost Precision and Reliability

Integrating smart technologies into operational frameworks is revolutionizing how industries achieve higher precision and reliability. By incorporating advanced data analytics and automation, organizations can now monitor processes in real-time, identify inefficiencies, and adjust parameters on the fly to ensure consistent outcomes. For example, in manufacturing, IoT sensors paired with AI-driven algorithms detect minute variations in production lines, enabling proactive maintenance and minimizing errors. This seamless blend of digital tools not only enhances accuracy but also builds a robust foundation for dependable operations across diverse sectors.

The adoption of smart technologies like machine learning and edge computing further amplifies reliability by learning from historical data and predicting potential disruptions. These systems analyze vast datasets to forecast equipment failures or supply chain bottlenecks, allowing companies to implement preemptive measures rather than reactive fixes. In healthcare, integrating these technologies has led to more accurate diagnostic tools and personalized treatment plans, significantly reducing human error and improving patient outcomes. This forward-thinking approach transforms reliability from a static goal into a dynamic, continuously improving process.

To truly stand out in today's competitive landscape, businesses must go beyond basic implementation by customizing smart technology integration to their unique needs and challenges. This might involve developing proprietary algorithms or combining multiple technologies to create synergistic effects. For instance, in logistics, integrating GPS tracking with predictive analytics optimizes delivery routes and inventory management, ensuring timely and precise service. By fostering innovation and tailoring solutions, companies not only boost precision and reliability but also carve a distinct niche that sets them apart from competitors.

Tailoring Design Strategies to Meet Specific Client Requirements

When it comes to design, one-size-fits-all approaches often fall flat because each client brings a unique set of needs, goals, and constraints to the table. Tailoring design strategies starts with a deep dive into understanding these specifics. This isn't just about asking standard questions; it involves listening intently to uncover underlying challenges, budget realities, and even the unspoken preferences that shape a project's direction. By immersing ourselves in the client's world—whether it's a startup aiming for rapid market entry or an established brand seeking a fresh identity—we can craft strategies that feel bespoke rather than borrowed.

What sets effective customization apart is the ability to blend creativity with pragmatism. Instead of relying on generic templates, we map out design solutions that align precisely with client timelines, resources, and target audiences. This might mean prioritizing modular elements for a client needing scalable updates or emphasizing user-centric interfaces for those focused on engagement. The magic happens when design isn't just aesthetically pleasing but becomes a strategic tool that addresses real-world demands, making every visual choice and functional detail a deliberate step toward the client's success.

Ultimately, tailored design strategies thrive on ongoing collaboration, where feedback loops refine the approach as projects evolve. This dynamic process ensures that the final output isn't just a static deliverable but a living solution that adapts to shifting requirements. By keeping the dialogue open and the strategy flexible, we deliver designs that not only meet but often exceed expectations, proving that the best results emerge when creativity is guided by a client's distinct vision.

FAQ

Implementing lean manufacturing principles, such as waste reduction and continuous flow, alongside advanced automation technologies like robotic assembly lines can significantly boost efficiency.

By optimizing supply chain management, using cost-effective materials without compromising quality, and adopting energy-efficient processes to lower operational expenses.

Integrating real-time monitoring systems and predictive maintenance helps prevent defects early, reducing rework and downtime, thus maintaining high throughput and reliability.

Customization meets diverse client needs, but it can be streamlined through modular designs and flexible production lines that allow quick adjustments without disrupting overall workflow.

By analyzing production data to identify bottlenecks, forecast demand, and optimize resource allocation, enabling data-driven decisions for smoother operations and better planning.

Challenges include supply chain disruptions and skill gaps; solutions involve diversifying suppliers, investing in employee training, and leveraging digital tools for enhanced resilience and adaptability.

Conclusion

The title "Maximizing Efficiency in ODM Combiner Box Manufacturing: A Guide for Modern Factories" highlights a comprehensive approach to enhancing factory performance through strategic improvements. By streamlining assembly lines and integrating smart technologies like IoT sensors and automation, production speed and precision are significantly boosted, reducing manual errors and downtime. This synergy between optimized workflows and cutting-edge tools ensures reliability in combiner box output, meeting the rigorous demands of modern energy systems. Additionally, tailoring design strategies to specific client requirements fosters customization without sacrificing efficiency, allowing factories to adapt quickly to diverse market needs while maintaining high-quality standards.

Further efficiency gains are achieved by implementing robust quality control protocols and leveraging sustainable materials, which minimize defects and promote eco-friendly manufacturing practices. This not only reduces waste and rework costs but also enhances brand reputation in an increasingly environmentally conscious industry. Optimizing supply chain logistics adds another layer of cost-effectiveness by ensuring timely material delivery and minimizing inventory bottlenecks. Together, these strategies create a holistic framework that modern factories can adopt to thrive, balancing speed, quality, sustainability, and customization to maximize overall operational efficiency in ODM combiner box production.

Contact Us

Contact Person: Jack

Email: [email protected]

Tel/WhatsApp: (+86) 13757759651

Website: https://www.singi.com